VPSA Oxygen Generator

Technical Specifications

Capacity : 200 NM3/hr to 5000 NM3/hr

Purity : Up to 95%

Pressure : Up to 1.3-Bar without Oxygen booster compressor

Dew Point : Up to (-) 40˚C

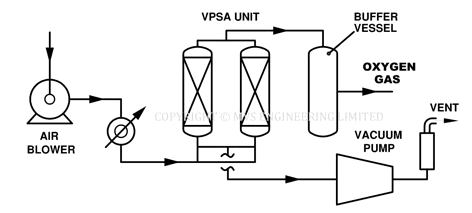

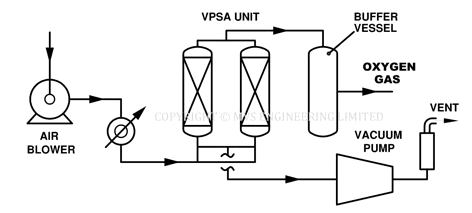

VPSA Principle

This process consists of 2 beds filled with Molecular Sieves. These cycle alternately in Production and in Regeneration. Regeneration of Molecular sieves is done by assistance of a Vacuum pump. The waste gas is 85% Nitrogen and 15% Oxygen which is vented to atmosphere. Product Oxygen gas purity is 90 to 95%.

Reliable, well-proven technology

VPSA technology has been used in MVS Oxygen generators for several years and our generators are operating successfully around the world. VPSA technology is time tested and very well proven in the field.

Fast Startup

VPSA Oxygen Gas Plants can be turned ON and OFF on-demand with the push of a single button. MVS VPSA units only require 15 minutes to start producing high purity Oxygen and there isn’t a need for the unit to be running when you are not consuming Oxygen gas. This is unlike the cryogenic Oxygen plants where the unit has to be kept running whether Oxygen is needed or not.

Industrial Uses

MVS VPSA Oxygen Generators are widely used across many industries including:

Paper and Pulp industries for Oxybleaching and delignification

Glass industries for furnace enrichment

Metallurgical industries for oxygen enrichment of furnaces

Chemical industries for oxidation reactions and for incinerators

Water and Wastewater treatment

Models

MVS offers a variety of models from 200 to 5000 NM3/hr Oxygen capacity needs.

Write a review

Your Name:Your Review: Note: HTML is not translated!

Rating: Bad Good

Enter the code in the box below:

Description

Technical Specifications

Capacity : 200 NM3/hr to 5000 NM3/hr

Purity : Up to 95%

Pressure : Up to 1.3-Bar without Oxygen booster compressor

Dew Point : Up to (-) 40˚C

VPSA Principle

This process consists of 2 beds filled with Molecular Sieves. These cycle alternately in Production and in Regeneration. Regeneration of Molecular sieves is done by assistance of a Vacuum pump. The waste gas is 85% Nitrogen and 15% Oxygen which is vented to atmosphere. Product Oxygen gas purity is 90 to 95%.

Reliable, well-proven technology

VPSA technology has been used in MVS Oxygen generators for several years and our generators are operating successfully around the world. VPSA technology is time tested and very well proven in the field.

Fast Startup

VPSA Oxygen Gas Plants can be turned ON and OFF on-demand with the push of a single button. MVS VPSA units only require 15 minutes to start producing high purity Oxygen and there isn’t a need for the unit to be running when you are not consuming Oxygen gas. This is unlike the cryogenic Oxygen plants where the unit has to be kept running whether Oxygen is needed or not.

Industrial Uses

MVS VPSA Oxygen Generators are widely used across many industries including:

Paper and Pulp industries for Oxybleaching and delignification

Glass industries for furnace enrichment

Metallurgical industries for oxygen enrichment of furnaces

Chemical industries for oxidation reactions and for incinerators

Water and Wastewater treatment

Models

MVS offers a variety of models from 200 to 5000 NM3/hr Oxygen capacity needs.

Reviews (0)

Write a review

Your Name:Your Review: Note: HTML is not translated!

Rating: Bad Good

Enter the code in the box below: