Vacuum Insulated Cryogenic Pipe Systems

We can work from your isometric layout to provide vacuum insulated cryogenic pipe systems engineered for ease of installation as well as for optimum insulation efficiency. When placing an order, the customer has the choice of bayonet or field joint connections. A vacuum pump-out and relief assembly is provided on the outer ends of each pipe section. Vacuum insulated cryogenic pipe systems are typically made to fit shipping dimensions. Pipe segments are designed for ease of handling and protection in shipment.

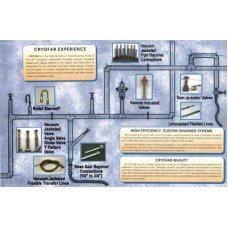

Cryofab Experience

Since 1971, Cryofab has been manufacturing "state of the art" cryogenic equipment including vacuum insulated vessels and piping. Experts in the design and fabrication of equipment for the ultimate cold fluid, liquid helium, Cryofab has the ability to custom manufacture high quality vacuum insulated cryogenic piping systems including bayonets, elbows, tees, crosses, valves and flexible hoses.

Cryofab Quality

All Cryofab vacuum insulated cryogenic pipe systems are designed, constructed, and tested with the satisfaction of the customer in mind. Multi-layer insulation and better materials are employed to maintain a high thermal efficiency for low heat leak.

The annular space is evacuated at a pressure of 1x10(-6) mm Hg. under 250°F heat and is tested with a helium mass spectrometer with 1x109 cc/sec sensitivity. Each vacuum insulated cryogenic pipe systems is inspected for conformance to our rigorous specifications before it can be released for shipment to the customer.

Efficient Vacuum Insulated Cryogenic Pipe Systems

Vacuum systems are much more efficient than "foam-insulated pipe" or "dynamic vacuum" systems for both insulating capabilities and cost effective operation.

A comparison of heat input from a normal environment into a liquid nitrogen flow stream:

- Foam Insulated Pipe: 12 to 20 BTU/hr-ft or vaporizing up to 2.5 gallons/hr*

- Dynamic-vacuum Pipe: 2 to 4 BTU/hr-ft or vaporizing up to .5 gallons/hr*

- Cryofab Vacuum Insulated Pipe: 0.42 BTU/hr-ft or vaporizing up to .08 gallons/hr*

Write a review

Your Name:Your Review: Note: HTML is not translated!

Rating: Bad Good

Enter the code in the box below:

Description

We can work from your isometric layout to provide vacuum insulated cryogenic pipe systems engineered for ease of installation as well as for optimum insulation efficiency. When placing an order, the customer has the choice of bayonet or field joint connections. A vacuum pump-out and relief assembly is provided on the outer ends of each pipe section. Vacuum insulated cryogenic pipe systems are typically made to fit shipping dimensions. Pipe segments are designed for ease of handling and protection in shipment.

Cryofab Experience

Since 1971, Cryofab has been manufacturing "state of the art" cryogenic equipment including vacuum insulated vessels and piping. Experts in the design and fabrication of equipment for the ultimate cold fluid, liquid helium, Cryofab has the ability to custom manufacture high quality vacuum insulated cryogenic piping systems including bayonets, elbows, tees, crosses, valves and flexible hoses.

Cryofab Quality

All Cryofab vacuum insulated cryogenic pipe systems are designed, constructed, and tested with the satisfaction of the customer in mind. Multi-layer insulation and better materials are employed to maintain a high thermal efficiency for low heat leak.

The annular space is evacuated at a pressure of 1x10(-6) mm Hg. under 250°F heat and is tested with a helium mass spectrometer with 1x109 cc/sec sensitivity. Each vacuum insulated cryogenic pipe systems is inspected for conformance to our rigorous specifications before it can be released for shipment to the customer.

Efficient Vacuum Insulated Cryogenic Pipe Systems

Vacuum systems are much more efficient than "foam-insulated pipe" or "dynamic vacuum" systems for both insulating capabilities and cost effective operation.

A comparison of heat input from a normal environment into a liquid nitrogen flow stream:

- Foam Insulated Pipe: 12 to 20 BTU/hr-ft or vaporizing up to 2.5 gallons/hr*

- Dynamic-vacuum Pipe: 2 to 4 BTU/hr-ft or vaporizing up to .5 gallons/hr*

- Cryofab Vacuum Insulated Pipe: 0.42 BTU/hr-ft or vaporizing up to .08 gallons/hr*

Reviews (0)

Write a review

Your Name:Your Review: Note: HTML is not translated!

Rating: Bad Good

Enter the code in the box below: