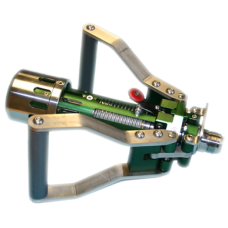

LNG Fueling Nozzle

SPECIFICATIONS:

Fluid Compatibility: LNG, Methane and LN2

Maximum Refueling Pressure: 250 PSIG/17.24 BAR

Maximum System Pressure: 500 PSIG/34.5 BAR

Burst Pressure: greater than 1,500 PSIG/103.5 BAR

Rated Flow: 50 GPM @ 250 PSIG (LNG)

Nozzle Weight: 10.4 LBS

Port Size: 1” Male SAE 37 degree flare (SAE J514) (1 5/16 -12 thd.)

Operating Temperature: -320°F to +140°F / -195°C to 60°C

FEATURES:

A positive “Vent Position” improves safety and provides a positive stop to release trapped gasses when removing the Nozzle.

Ball bearings lock the Nozzle in place during fueling and help guide the Nozzle and let it “roll” on and off easily.

Light weight design makes the Nozzle easier to handle over long work days and easier to slide onto the Receptacle.

Non-metallic bearings, air gaps, and insulation at key points are used to minimize ice issues.

Easy access for maintenance of the Receptacle end seal, poppet assembly and the poppet seat.

Reasonable cost while maintaining reliability.

Automatic Shutoff when disconnecting

Write a review

Your Name:Your Review: Note: HTML is not translated!

Rating: Bad Good

Enter the code in the box below:

Description

SPECIFICATIONS:

Fluid Compatibility: LNG, Methane and LN2

Maximum Refueling Pressure: 250 PSIG/17.24 BAR

Maximum System Pressure: 500 PSIG/34.5 BAR

Burst Pressure: greater than 1,500 PSIG/103.5 BAR

Rated Flow: 50 GPM @ 250 PSIG (LNG)

Nozzle Weight: 10.4 LBS

Port Size: 1” Male SAE 37 degree flare (SAE J514) (1 5/16 -12 thd.)

Operating Temperature: -320°F to +140°F / -195°C to 60°C

FEATURES:

A positive “Vent Position” improves safety and provides a positive stop to release trapped gasses when removing the Nozzle.

Ball bearings lock the Nozzle in place during fueling and help guide the Nozzle and let it “roll” on and off easily.

Light weight design makes the Nozzle easier to handle over long work days and easier to slide onto the Receptacle.

Non-metallic bearings, air gaps, and insulation at key points are used to minimize ice issues.

Easy access for maintenance of the Receptacle end seal, poppet assembly and the poppet seat.

Reasonable cost while maintaining reliability.

Automatic Shutoff when disconnecting

Reviews (0)

Write a review

Your Name:Your Review: Note: HTML is not translated!

Rating: Bad Good

Enter the code in the box below: