PSA Oxygen Generator

Technical Specifications

Capacity : 1 NM3/hr to 200 NM3/hr

Purity : Up to 95%

Pressure : Up to 4-Bar without Oxygen booster compressor

Dew Point : Up to (-) 40˚C

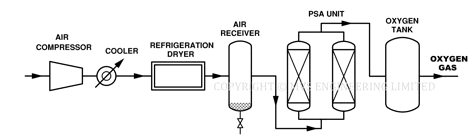

PSA principle

This process consists of 2 vessels filled with Molecular Sieves and Activated Alumina. Clean compressed air at 30° C temperature is passed through one vessel and oxygen comes out as product gas. The exhaust gas (Nitrogen) is discharged back into atmosphere. Upon saturation of the molecular sieve bed, the process switches Oxygen generation to the other bed by automatic valves, while allowing the saturated bed to undergo regeneration by depressurization and purging to atmospheric pressure. Thus 2-vessels keep cycling alternately in Oxygen production and regeneration ensuring Oxygen gas is continuously available to your process.

Continuous, uninterrupted supply and guaranteed purity

When you install the PSA Oxygen Gas plant on-site, you are in control of your Oxygen supply. If you are currently using cylinders, then there is always dependence on your suppliers and there is no guarantee of the purity of Oxygen being supplied. With PSA system, you can be sure of the purity of Oxygen with the included Oxygen purity analyzer.

Industrial Uses

Our PSA Oxygen Gas Generators are widely used across many industries including:

Paper and Pulp industries for Oxybleaching and delignification

Glass industries for furnace enrichment

Metallurgical industries for oxygen enrichment of furnaces

Chemical industries for oxidation reactions and for incinerators

Water and Wastewater treatment

Write a review

Your Name:Your Review: Note: HTML is not translated!

Rating: Bad Good

Enter the code in the box below:

Description

Technical Specifications

Capacity : 1 NM3/hr to 200 NM3/hr

Purity : Up to 95%

Pressure : Up to 4-Bar without Oxygen booster compressor

Dew Point : Up to (-) 40˚C

PSA principle

This process consists of 2 vessels filled with Molecular Sieves and Activated Alumina. Clean compressed air at 30° C temperature is passed through one vessel and oxygen comes out as product gas. The exhaust gas (Nitrogen) is discharged back into atmosphere. Upon saturation of the molecular sieve bed, the process switches Oxygen generation to the other bed by automatic valves, while allowing the saturated bed to undergo regeneration by depressurization and purging to atmospheric pressure. Thus 2-vessels keep cycling alternately in Oxygen production and regeneration ensuring Oxygen gas is continuously available to your process.

Continuous, uninterrupted supply and guaranteed purity

When you install the PSA Oxygen Gas plant on-site, you are in control of your Oxygen supply. If you are currently using cylinders, then there is always dependence on your suppliers and there is no guarantee of the purity of Oxygen being supplied. With PSA system, you can be sure of the purity of Oxygen with the included Oxygen purity analyzer.

Industrial Uses

Our PSA Oxygen Gas Generators are widely used across many industries including:

Paper and Pulp industries for Oxybleaching and delignification

Glass industries for furnace enrichment

Metallurgical industries for oxygen enrichment of furnaces

Chemical industries for oxidation reactions and for incinerators

Water and Wastewater treatment

Reviews (0)

Write a review

Your Name:Your Review: Note: HTML is not translated!

Rating: Bad Good

Enter the code in the box below: